by  ZOU

ZOU

Electronic products may introduce various defects due to the extensive use of materials such as components and complicated processing. Whether it is component defects or processing defects, it can be divided into obvious defects and potential defects. Obvious defects are defects that cause the product to malfunction, such as short circuits, open circuits, and the like. The potential defects make the product temporarily usable, but the defects will be exposed quickly during use, resulting in the product not working properly (such as solder joints, slight vibration may cause the solder joint to break and the product is not available).

Aging is the application of accelerated environmental stresses to electronic products, such as temperature stress, electrical stress, hot flash stress, mechanical stress, etc., in the harsh environment to promote the potential defects of the product to accelerate exposure to failure, to achieve the purpose of discovering and eliminating potential defects. , as far as possible to eliminate early failure before normal use. The products that pass the aging process enter a stable period of high reliability.

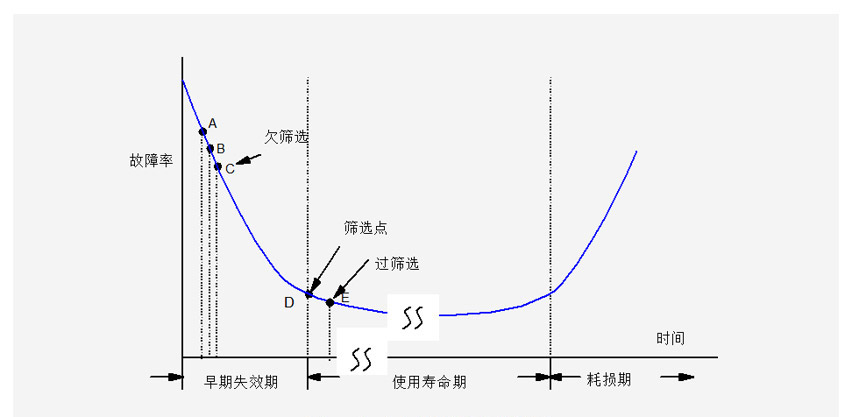

The theoretical basis of aging is the failure rate curve of the electronic product (referred to as the bathtub curve), as shown in Figure 1. Aging is aimed at exposing potential defects and eliminating early failures. Points A, B and C in the figure indicate that the degree of aging is insufficient, and a large proportion of defects still flow into the market after aging. The ideal aging point is point D in the figure, and the selection of point D is mainly based on empirical data. The E point is over-aged, which not only increases the cost of aging, but also destroys the original good product, thereby shortening the service life of the product.

Figure 1 Electronic product failure rate graph

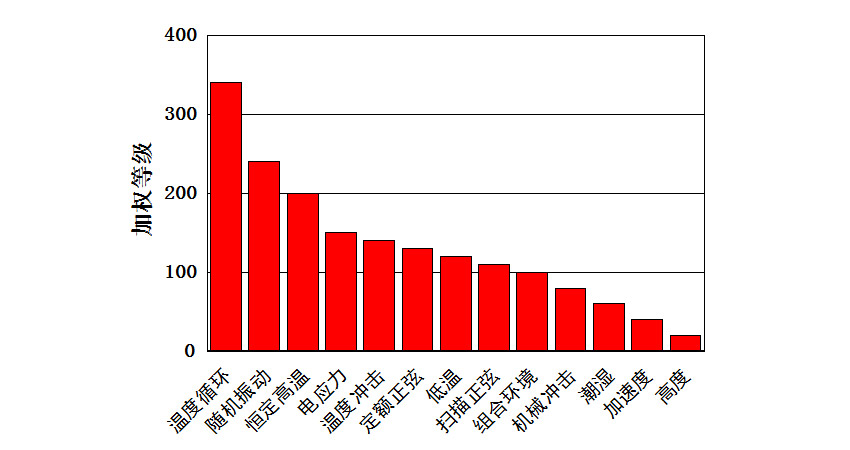

The effect of aging is also related to the type of environmental stress applied. The common environmental stress aging effect is shown in Figure 2, where the temperature cycle has the best aging effect.

Figure 2 Comparison of various environmental stress aging effects

According to the previous failure analysis statistics and the tolerable temperature of various materials, the aging mode of our products is set at 72 hours, high temperature cycle of -40~85 °C, theoretically 100% screening of early failure products, The products that flow into the hands of the customers are the quality products that have withstood the test.